Amber Song

Overview:

Electric contact pressure gauges are widely used in petroleum, chemical, metallurgical, power station, machinery and other industrial sectors or electromechanical equipment to measure the pressure of various fluid media without explosion hazard. Usually, the meter is used with the corresponding electrical components (such as relays and inverters) to automatically control and signal (alarm) the various gases and liquid media under test (control) pressure.

structure:

The electric contact pressure gauge is composed of a measuring system, an indicating system, a magnetic auxiliary electric contact device, a casing, an adjusting device, and a junction box (plug socket). The general electric contact pressure gauge is used to measure the positive and negative pressure of gas and liquid medium which does not corrode copper and copper alloy. The stainless steel electric contact pressure gauge is used to measure the positive and negative of gas and liquid medium which are not corrosive to stainless steel. The pressure sends a signal when the pressure reaches a predetermined value, and the control circuit is turned on to achieve the purpose of the automatic control alarm.

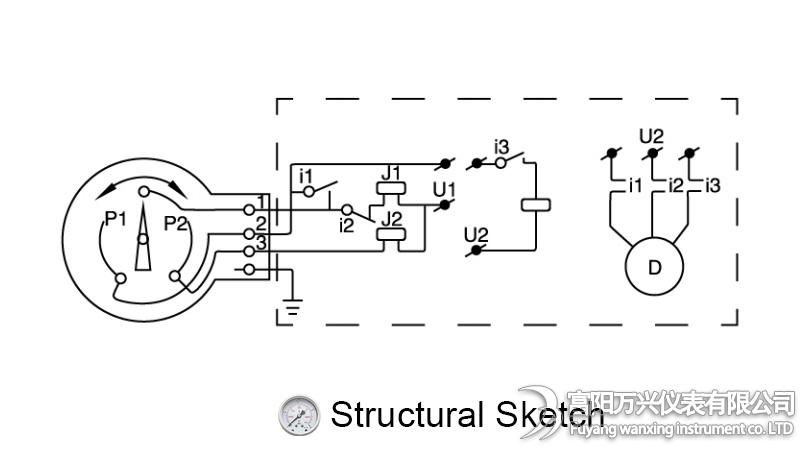

The electric contact pressure gauge is based on the spring tube in the measuring system under the pressure of the measured medium, forcing the end of the spring tube to produce a corresponding elastic deformation-displacement, which is driven by the gear through the gear transmission mechanism and amplified by the fixed gear The indication (along with the contacts) indicates the measured value on the dial. At the same time, when it comes into contact with the contact (upper or lower limit) of the set pointer (the upper or lower limit), the circuit in the control system can be disconnected or turned on to achieve automatic control and transmission. The purpose of the letter alarm.

Take the control of the compressor motor as an example: the gas storage pressure reaches the lower limit and automatically opens, and the upper limit is automatically stopped.

The control process is as follows: when the pressure reaches (or when the switch is low), the active contact of the electric contact pressure gauge (the common end of the power supply) is connected with the lower limit contact, the relay J1 acts and self-locks, and its normally open contact The drive J3 is closed and the motor is energized. When the pressure reaches the upper limit, the movable contact is connected to the upper limit contact, the relay J2 is actuated, the normally closed contact is opened, the J1 power supply is cut off, the normally open point is disconnected, J3 is released, and the motor is stopped. This reciprocates to achieve the purpose of automatic control.

Material selection:

The material of the electric contact pressure gauge is: copper alloy, 304 stainless steel or 316 stainless steel.

In view of the fact that this series of instruments not only has the characteristics of novel design, reliable structure, complete specifications, good stability and adaptability, but also has the advantages of good measurement and control, simple installation and small maintenance, it is generally no indication. The pressure measurement and control instrument is unmatched by the pressure controller without switching difference adjustment and without external setting device.

Types of:

In order to meet the requirements of the object to be tested (with seismic or corrosion resistance and explosion-proof requirements), you can use the seismic resistance contact pressure gauge or corrosion-resistant electrical contact pressure gauge and explosion-proof electrical contact pressure gauge.

Ordinary electric contact pressure gauges are suitable for measuring the pressure of gases and liquids that are not corrosive to copper alloys and iron.

Anti-corrosion type electric contact pressure gauge The main pressure measuring components and instrument housing are designed with stainless steel material, which is suitable for measuring the pressure of corrosive gas and liquid.

The anti-corrosion and anti-vibration type electric contact pressure gauge ensures oil-free display by using liquid damping by filling the surface of the watch body, and is suitable for measuring places with strong pulsation of the medium and large environmental vibration.

Explosion-proof electrical contact pressure gauges are suitable for use in hazardous locations where there is an explosive mixture in the environment.

Installation method

1 · Radial direct installation

2 · Axial direct mounting

3 · Direct mounting on the front of the radial belt

4. Direct installation of the front side of the axial belt

At last ,you can choose the code by yourself according to below form.

Contact: can cheng

Phone: 860+13685798996

Tel: 0086+0571-63139798

Email: fywxyb@163.com

Add: 756, Sun Jia lane, autumn rich spring street, Fuyang District, Hangzhou City, Zhejiang Province, China